FlexElement Special Purpose Couplings

High-Performance Coupling Products

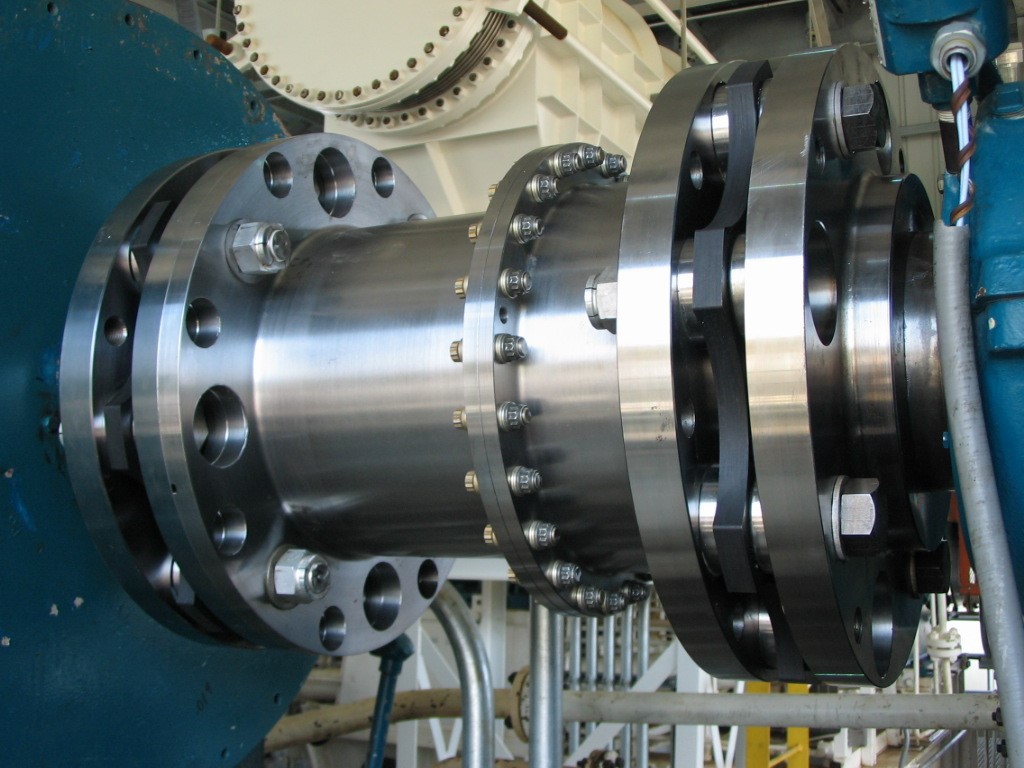

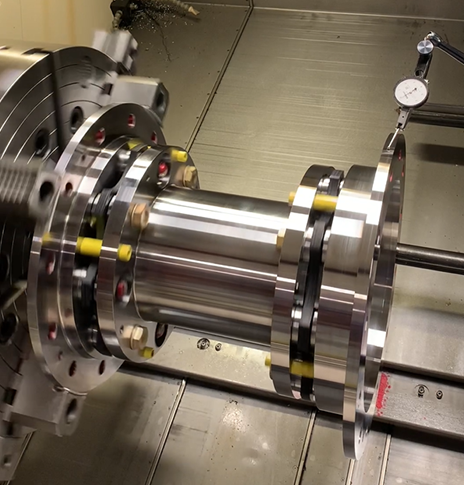

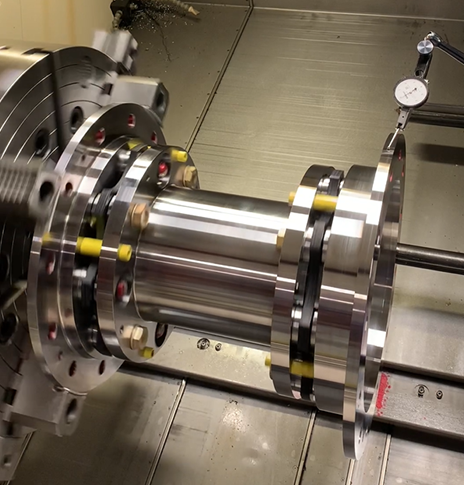

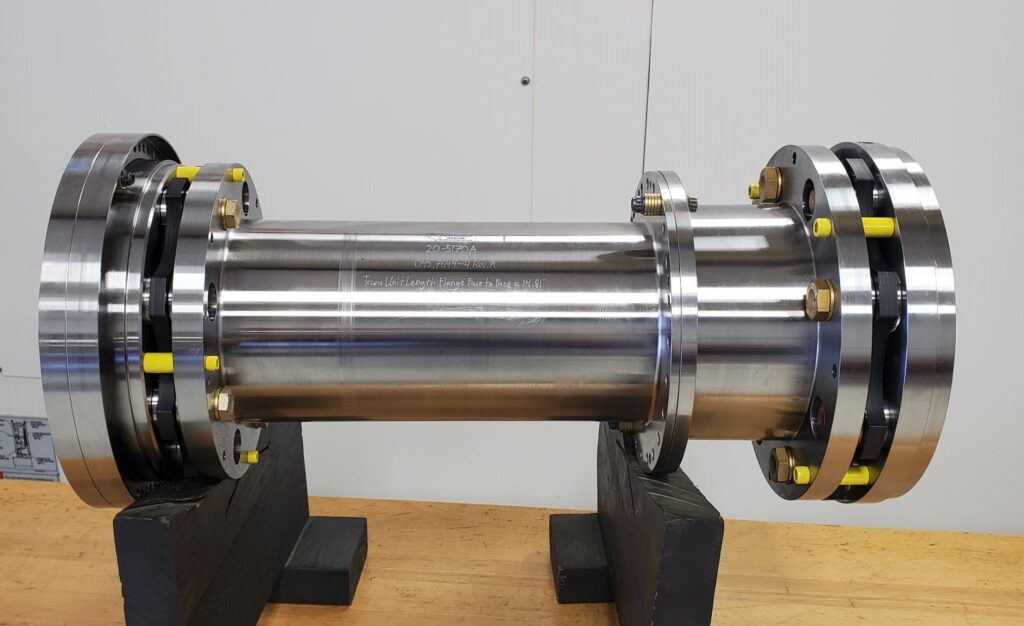

Starting in 1980, FlexElement design engineering personnel created a range of standardized high-performance couplings in compliance with A.P.I. 671 Specification. The resulting products have been manufactured by FlexElement since 1991, incorporating design improvements and new applications along the way. These couplings have been successfully used on critical turbomachinery applications worldwide.

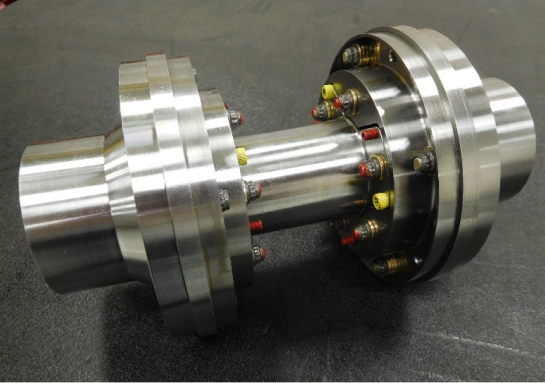

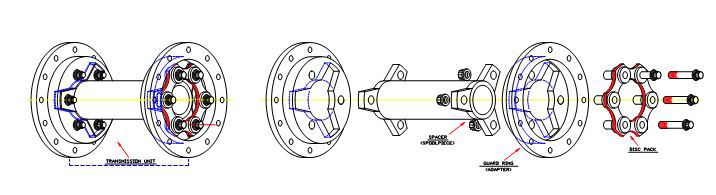

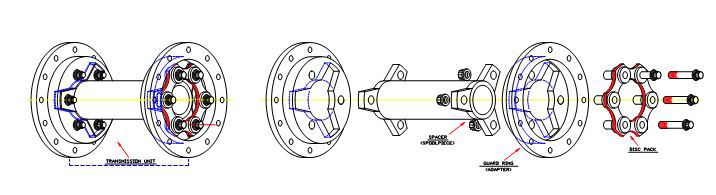

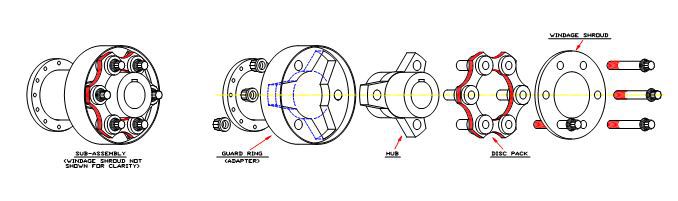

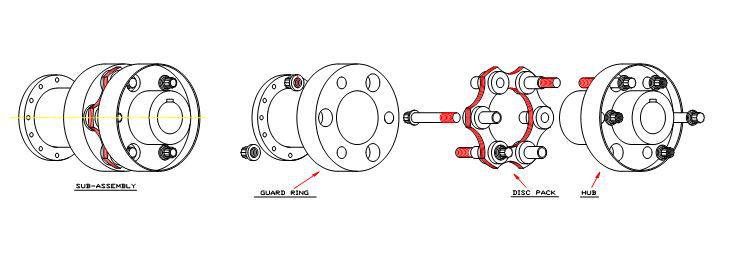

In the marine style configurations, the flexible elements are incorporated as part of the transmission unit to simplify installation and removal.

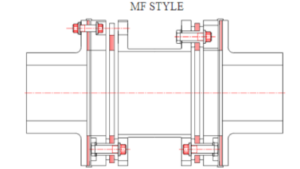

- Basic marine style coupling.

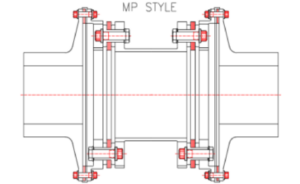

- Marine style coupling with unshrouded elements and standard flanges.

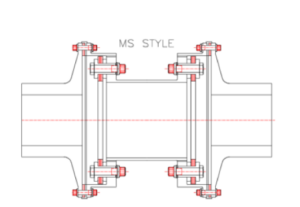

- Marine style coupling with shrouded elements and co-planer interlocking flanges.

Want more info on these products?

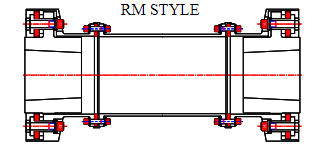

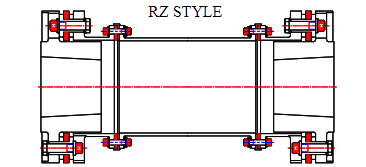

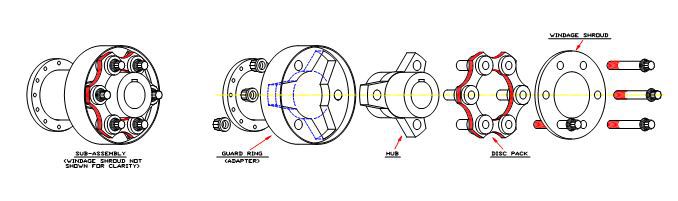

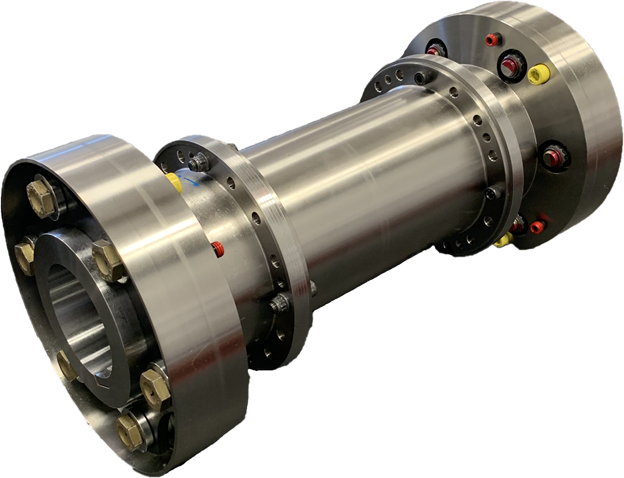

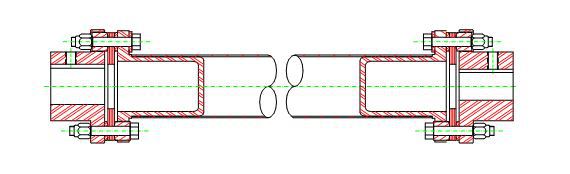

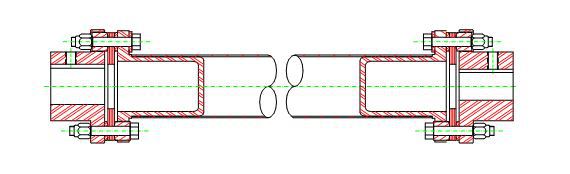

Contact UsIn the reduced moment configurations, the flexible elements are moved over the shaft end, as close to the shaft bearings as possible, to reduce overhung mass.

- A reduced moment coupling with shrouded elements and co-planer interlocking drive flanges.

- A reduced moment coupling with standard drive flanges.

Want more info on these products?

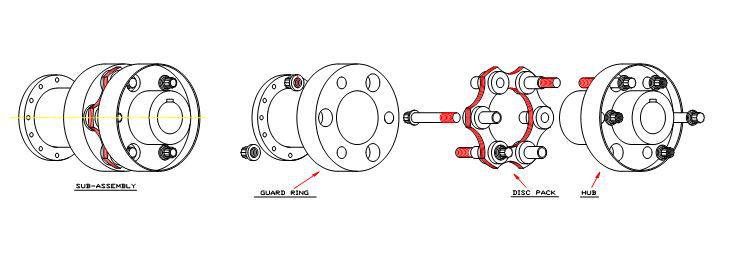

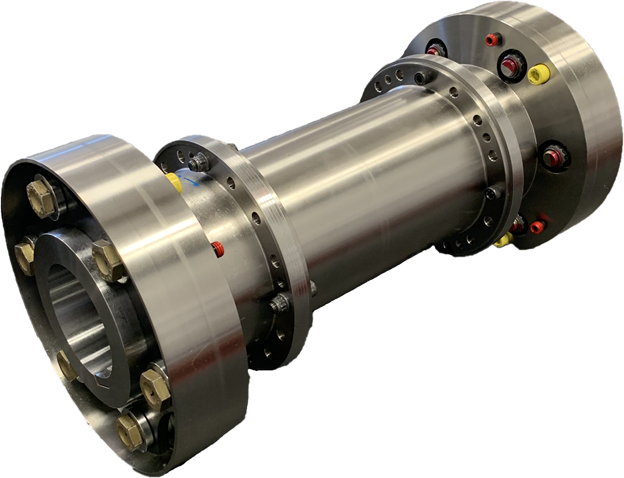

Contact UsThe 50/50 configurations couple marine style and reduced moment designs and can incorporate any combination of shaft end geometries to fit your coupling needs.

Want more info on these products?

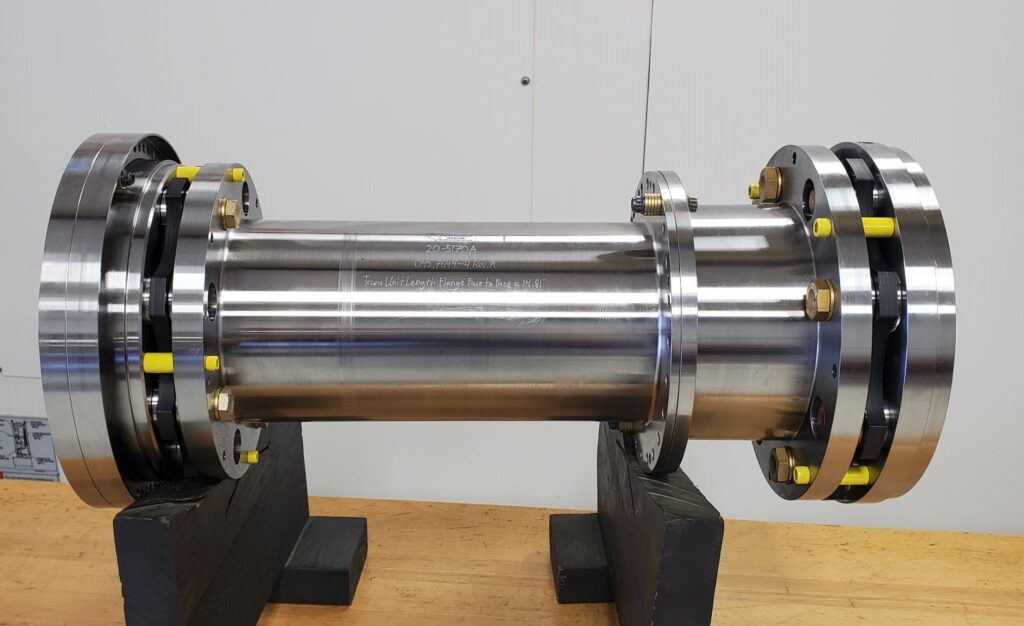

Contact UsA close-coupled design is made specifically for close proximity machines with minimal distance between shaft ends.

Want more info on these products?

Contact UsDriveshafts specifically designed for longer span applications requiring lighter weight components. Made of composite tubing, these couplings weigh a fraction of a steel coupling and are a suitable replacement for your application.

Want more info on these products?

Contact UsFrom hydraulic tooling like pushers and pump kits to ring and plug gauges, FlexElement can provide you with the items necessary to ensure successful installation and removal.

Want more info on these products?

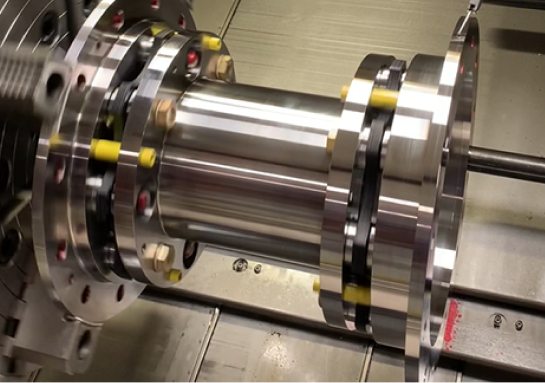

Contact UsRepair kits include all the parts necessary to restore your coupling to like-new condition, including required disc packs, bushings, drive hardware, stripper hardware, and gagging hardware. Better yet, send the coupling to us, and we will refurbish it for you!

Want more info on these products?

Contact UsOur products are delivered on time with easy-to-follow installation instructions and ongoing product support.

Don't see what you're looking for?

Contact us now to build a solution that is right for you!

We're here to help.

Find additional information and answers to our most common coupling questions here.